A.Rooban-tharsy

Tuesday, 30 April 2013

Concrete Mix design......

Fresh concrete is in mouldable condition to do the concreting properly without honey comb or crack.

Workability

The workability covers the following properties,

Mobility

Compactibility

Finishability

Pumpability

These concrete properties will varies for given construction situation/ Elements.

Workability Test Methods

There are various tests are available to compute the workability, but the common method is SLUMP TEST.

The Vebe test and Tattersall 2 point test are may be used in research laboratories. but they are rarely used in the field.

There are two reason to specifying a Workability test method for fresh concrete,

1. Control of workability within a range to the construction condition , transporting equipment , placing

equipment and compacting method.

2. Control of the water content (Indirectly )

ie; (water /cement) ratio

Saturday, 27 April 2013

Anchorage detailing -( IStructE guide)

Introduction

Design forces in the rebar can be developed by anchorage / lap length in concrete structure.

fully anchorage detail for Shear links

Lap lengths

The lap length for the tension bar should be provision to develop the required stress in the reinforcement. The lap length for unequal size of the rebars may based on smaller size bar lap length.

The lap length for the compression should be atleast 25% grater than the compression anchorage length to develop the required stress in concrete. The lap length for unequal size of the rebars may based on smaller size bar lap length.

Hooks ,bends and bearing lengths.

Minimum bending radius & Anchorage may be govern certain aspects of design. Eg, depth of bearing and choice rebar size for a given thickness of slab. Refer to below table for minimum radius for each size bar and effective anchorage length.

Corbels and nips

Design forces in the rebar can be developed by anchorage / lap length in concrete structure.

fully anchorage detail for Shear links

Lap lengths

The lap length for the tension bar should be provision to develop the required stress in the reinforcement. The lap length for unequal size of the rebars may based on smaller size bar lap length.

The lap length for the compression should be atleast 25% grater than the compression anchorage length to develop the required stress in concrete. The lap length for unequal size of the rebars may based on smaller size bar lap length.

Hooks ,bends and bearing lengths.

Minimum bending radius & Anchorage may be govern certain aspects of design. Eg, depth of bearing and choice rebar size for a given thickness of slab. Refer to below table for minimum radius for each size bar and effective anchorage length.

Curtailment of reinforcement

In every flexural members except at end of supports every bar should extent beyond the point which it is no longer needed, this distance at least equal to the grater of effective depth of member or twelve times of the bar size.

In the bar in tension zone, one of the following distance for all arrangements of design ultimate load

a) Anchorage length appropriates to it's design strength (0.87x fy ) from the point at which it is no longer required to resisting the bending moment

b)To the point where the design shear capacity of the section is grater than twice the design shear force at that section

c) To the point where the other bars continuing past that point provide double the area required to resist the design bending moment at that section.

Corbels and nips

Friday, 26 April 2013

Design of Cantilever precast wall

Introduction

this wall's are usually provided for staircase and lift shafts. they are design as conventional rc walls, but the connection detail of vertical and horizontal joints transfer the compression , Bending moment and shear force.

Failure modes

1. Shear slip

shear slip at the horizontal and vertical joints (when the L/h grater than 3 refer to below figure)

2. Flexural tension failure

Due to large overturning moment & small axial load. (refer to below figure)

3. Flexural compression failure

Due to combination of Axial force and Bending moment. ( refer to below figure)

Design of Cantilever precast wall

this wall's are usually provided for staircase and lift shafts. they are design as conventional rc walls, but the connection detail of vertical and horizontal joints transfer the compression , Bending moment and shear force.

Failure modes

1. Shear slip

shear slip at the horizontal and vertical joints (when the L/h grater than 3 refer to below figure)

2. Flexural tension failure

Due to large overturning moment & small axial load. (refer to below figure)

3. Flexural compression failure

Due to combination of Axial force and Bending moment. ( refer to below figure)

Design of Cantilever precast wall

Built-up column I section design & tensile test for fillet weld.

Brief introduction

Due to site constraint we have to design built up columns instead of universal column, so the design of welding must be consider the major axis bending moment. The axial force and shear force directly accountable with normal design procedures.

Design equation

Horizontal shear per welding = (S x A x y) / ( 2 x Ix )

A = Flange Area

S = M / (D-t) ; M - major bending moment , D - flange to flange depth ,

t = flange thickness

y = lever arm from center of gravity

Ix = Moment of inertia about X axis

From the above equation we can find the required welding force per mm length.

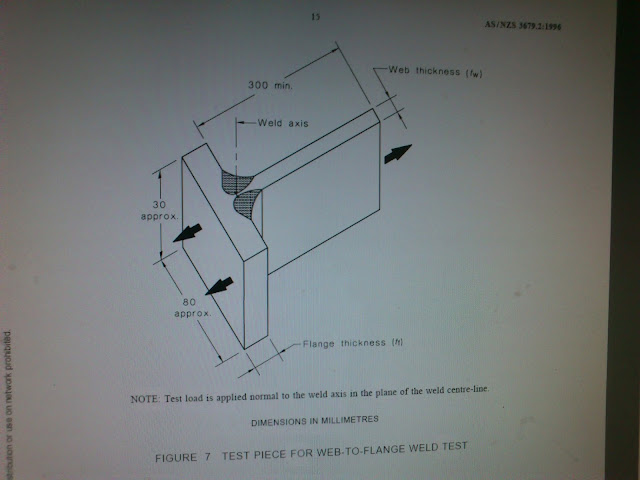

Tensile test for fillet weld

The welding normally subjected to nondestructive testings, such as magnetic particle inspection , ultrasonic inspection. But the critical strength required section need to test for tensile strength. this testing method statement only provided in the AS/NZS 3679.2:1996 code.

Sample test result

Due to site constraint we have to design built up columns instead of universal column, so the design of welding must be consider the major axis bending moment. The axial force and shear force directly accountable with normal design procedures.

Design equation

Horizontal shear per welding = (S x A x y) / ( 2 x Ix )

A = Flange Area

S = M / (D-t) ; M - major bending moment , D - flange to flange depth ,

t = flange thickness

y = lever arm from center of gravity

Ix = Moment of inertia about X axis

From the above equation we can find the required welding force per mm length.

Tensile test for fillet weld

The welding normally subjected to nondestructive testings, such as magnetic particle inspection , ultrasonic inspection. But the critical strength required section need to test for tensile strength. this testing method statement only provided in the AS/NZS 3679.2:1996 code.

Sample test result

Thursday, 25 April 2013

Concrete rectification work / casting with aged concrete

The crack / honeycomb rectification shall be carried out using non shrinkage grout with pressure grouting in the construction industry. but for the large patching / rectifying works concrete casting acceptable with recommended bonding agents given below

Wednesday, 20 January 2010

Subscribe to:

Comments (Atom)